|

AMERICAN SOLVING INC

●

6519 EASTLAND PLAZA, BROOK PARK OHIO

(USA) ●

PH. 800.822.2285

●

PH.

440.234.7373

|

Toll Free:

1-800-822-2285

HOME PAGE

Drop Down Menu Creator by Vista-Buttons.com v5.7

Aqua Button

Generator by Vista-Buttons.com v5.0.0

Aqua Button

Generator by Vista-Buttons.com v5.0.0

|

|

AIR BEARINGS and AIR CASTERS

How Air Film Technology Works!

|

|

|

What is an Air Bearing or

Air Caster?

|

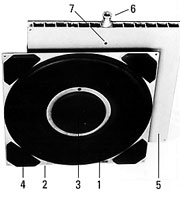

Air

Bearings are also known as Air Casters, they are one in the

same. An air caster / air bearing is made of reinforced

rubber. The circular rubber torus (bellow, item #1) is

vulcanized to an anodized aluminum back plate (item #2). When

the air bearing is deflated, the load rests on the landing pad

in the center of the module (item #3).

On larger capacity

models the air caster also includes landing pads in the the

corners (Item #4) for added support. The aluminum

back plate is bolted to a rigid load platform (item #5).

The load module top plate is an aluminum extrusion,

with a very high strength to weight ratio.

The supply of compressed air enters through a port in

the end of the module (item #6), then through the torus

(bellows) forcing a thin air film on which the load floats

with a minimum of friction.

A seal is formed between the floor surface and the

torus.

|

|

|

|

How Air Bearings

Work?

Modules are fitted to a special

load platform or individually positioned directly under the load. In order

to achieve stability, at least three, but most often four, modules are

placed under the load. (The “three-legged stool” principle.) These are

connected through a pneumatic control unit, to a compressed air supply.

Modules should be positioned as far apart as possible in order to optimize

the weight distribution and load stability. Once the modules have been

positioned, the valves can be opened individually. The pressure in the air

bearings can be increased slowly until they lift the load and it starts to

float. The load can then be moved and be positioned exactly as required. |

|

Operation of Air Bearings / Casters |

|

WHEN ENERGIZED

WITH A COMPRESSED AIR SUPPLY, THE FOLLOWING SEQUENCE OF EVENTS

TAKES PLACE |

|

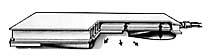

1.) The circular reinforced

rubber bellows inflates and fills the gap between the mounting

plate and the floor. |

|

|

2.) As the pressure increases,

the mounting plate and its landing pads, lifts off the floor.

|

|

|

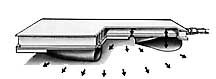

3.) When the pressure in the

bellows is higher than the counter pressure of the load, the

air flows out from the bellows forming a thin air film on

which the load floats practically friction-free.

|

|

TECHNICAL SPECIFICATIONS

|

|

Load |

Air Bearing |

Capacity |

Air |

Air |

Lifting |

Lift |

Support |

|

|

|

|

|

|

Module |

Element |

(lbs) |

Press. |

Cons. |

Height |

Area |

Area |

A |

B |

C |

D |

E |

|

Type |

Type |

|

(psi) |

(SCFM) |

in |

(sq in) |

(sq. in) |

(in) |

(in) |

(in) |

(in) |

(in) |

|

|

|

|

(1) |

(2) |

(3) |

|

(4) |

|

(5) |

|

|

(5) |

|

ML 8L |

ME 8L-0.3-LP |

500 |

13 |

8-24 |

3/8 |

38 |

5 |

8 |

0.83 / 1.6 |

0.39 |

1.22 / 2.00 |

0.25 / 0.75 |

|

ML 12L |

ME 12L-0.5-LP |

1,200 |

14 |

10-34 |

3/4 |

85 |

14 |

12 |

0.83 / 1.6 |

0.39 |

1.22 / 2.00 |

0.25 / 0.75 |

|

ML 8S |

ME 8S-0.6-LP |

1,000 |

26 |

11-32 |

3/8 |

38 |

5 |

8 |

0.83 / 1.6 |

0.39 |

1.22 / 2.00 |

0.25 / 0.75 |

|

ML 12S |

SE 12S-1.8-LP |

3,850 |

43 |

15-52 |

3/4 |

85 |

14 |

12 |

0.83 / 1.6 |

0.39 |

1.22 / 2.00 |

0.25 / 0.75 |

|

ML 15S |

SE 15S-2.5-LP |

5,500 |

43 |

15-61 |

7/8 |

133 |

20 |

15 |

0.83 / 1.6 |

0.39 |

1.22 / 2.00 |

0.25 / 0.75 |

|

ML 21S |

ME 21S-3.5-LP |

8,500 |

32 |

15-91 |

1 |

262 |

40 |

21 |

1.6 |

0.67 |

2.28 |

0.75 |

|

ML 27S |

ME 27S-6.0-LP |

14,000 |

32 |

15-122 |

1-1/4 |

433 |

155 |

27 |

1.6 |

0.94 |

2.56 |

0.75 |

|

ML 36S |

ME 36S-11-LP |

25,000 |

32 |

24-152 |

2 |

770 |

294 |

36 |

1.6 |

1.18 |

2.80 |

0.75 |

|

ML 48S |

ME 48S-20-LP |

45,000 |

32 |

30-182 |

3 |

1369 |

558 |

48 |

1.6 |

1.18 |

2.80 |

0.75 |

|

ML 60S |

ME 60S-30-LP |

70,000 |

32 |

46-228 |

3 |

2409 |

1042 |

60 |

1.6 |

1.22 |

2.83 |

0.75 |

|

ML 15H |

ME-15H-3.5-LP |

8,000 |

58 |

25-102 |

7/8 |

133 |

20 |

15 |

1.6 |

0.39 |

2.00 |

0.75 |

|

ML 21H |

ME 21H-70-LP |

17,000 |

63 |

27-163 |

1 |

262 |

93 |

21 |

1.6 |

0.67 |

2.28 |

0.75 |

|

ML 27H |

ME 27H-12-LP |

28,000 |

65 |

27-217 |

1-1/4 |

433 |

155 |

27 |

1.6 |

0.94 |

2.56 |

0.75 |

|

ML 36H |

ME 36H-20-LP |

50,000 |

63 |

43-271 |

2 |

770 |

294 |

36 |

1.6 |

1.18 |

2.80 |

0.75 |

|

ML 42H |

ME 42H-30-LP |

66,000 |

63 |

42-270 |

2-1/2 |

1200 |

409 |

42 |

1.6 |

1.18 |

2.80 |

0.75 |

|

ML 48H |

ME 48H-40-LP |

90,000 |

64 |

54-325 |

3 or 2 |

1369 |

1042 |

48 |

1.6 |

1.18 |

2.80 |

0.75 |

|

ML 60H |

ME 60H-60-LP |

140,000 |

64 |

81-407 |

3 |

2409 |

1042 |

60 |

1.6 |

1.22 |

2.83 |

0.75 |

|

|

1.) Air pressure in air air bearing element at capacity.

2.) Actual air consumption depends on the effective load and the

floor quality.

3.) Nominal lifting height ± .2

inches at max load

4.) Support area with

deflated air bearing module

5.) Cast aluminum load

module / Extruded aluminum load module |

AIR CASTERS

Air Film Technology

Air Bearings for Heavy Load Handling. The latest on

Air Film Technology in the Material Handling Industry. Replacement

Air Casters, Rentals, rigging equipment and Air Film Systems. Also

Wheeled vehicles with omni-directional steering for handling heavy

loads.

"Float Heavy

Loads on Air" |

| |

|

|

|

"Float Heavy Loads

on Air" |