|

AMERICAN 6519 Eastland Plaza Brook Park, OH 44142 PH. 800-822-2285 E-Mail: Sales@SolvingInc.com |

|

PRODUCTS: |

|

How they work! |

|

APPLICATIONS: |

|

REQUEST INFO: |

|

All Contact Info PH. 1-800-822-2285 |

|

FOR SALES: sales@solvinginc.com |

AIR CASTERS

Air Film Technology

Air Casters for Heavy Load Handling on a bearing of air. The latest on Air Film Technology in the Material Handling Industry. Replacement Air Casters, Rentals, rigging equipment and Air Film Systems. Also Wheeled vehicles with omni-directional steering for handling heavy loads.

"Float Heavy

Loads on Air"

HEAVY LOAD WHEELED VEHICLES

WHEELED TRANSPORTERS FOR THE MATERIAL HANDLING OF HEAVY LOADS

Wheel-based handling solutions

Solving heavy load handling systems are based on either air bearings or wheels, or a combination of both. The wheeled solutions are used in applications where the floor is not suitable for air bearings and in applications for both indoor and outdoor use.

|

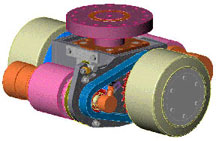

One of the industry leading features of our wheeled transporters and Automatic Guided Vehicles (AGV's) is the 'On-Center Rotation', and 'Fluid Suspension' - enabling these axle assemblies to turn in ANY direction under full load. By sharing fluid with the surrounding axle assemblies, it allows our wheel assemblies to operate over highly irregular floor surface conditions. The Wheeled transporters are available as both hydraulic electric or hydraulic motor driven equipment.

|

Designed specifically for in-plant operations, the Wheelift design allows much lower deck heights and heavier capacities in the more compact packages needed to operate indoors in highly congested plant areas and to travel down narrow intersecting aisles. The suspension and all-directional steering of Wheelift all-wheel driven AGVs and operator driven transporters are key elements that make very heavy load capacity vehicles possible.

|

HEADED & HEADLESS WHEELED TRANSPORTERS |

|

WHEEL & AXLE ASSEMBLIES ABOVE: a four axle transporter in which each axle has independent on-center rotation; a vertical lifting, fluid suspension, center column; wide face solid urethane tires; electric motor drives on every wheel; and the ability to tilt laterally to +/- 4 degrees to provide fully equalized loading across every wheel, regardless of the surface conditions. (under Transporter shot)

|

The "Headed" Transporter, Pictured Above: is referred to as having a “headed” configuration. That is, it has a raised engine and controls compartment at one end of the transporter to house the engine-driven generator package, the suspensions hydraulic power pack, and the electrical panels. In the “headed” or raised engine compartment versions, transporters are confined to entering and exiting the load in one direction. Also available is an extremely low profile “headless” transporters (shown bottom/left), where all of the engine/generator and control components are under the load platform deck. This allows the transporters to enter and exit loads from ANY direction. There are specific advantages to both configurations. Headless transporters are typically used in “tandem” operations where two, three, or four transporters align to carry large loads while operating as a single unit. Headless transporters can also drive through under several in-line units to handle progressive line moves. |

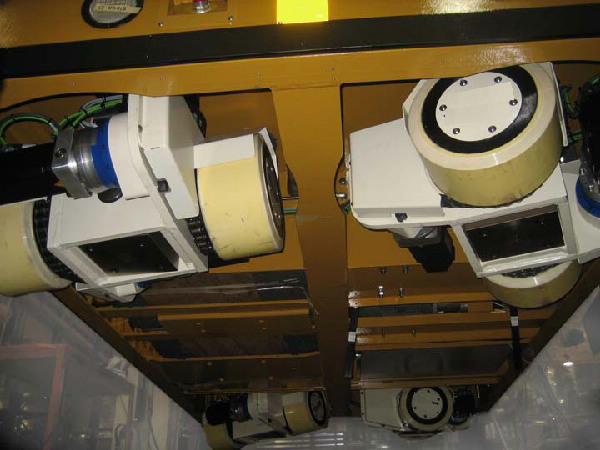

| The "Headless" Transporter Pictured Above: Illustrates two transporters in the final assembly phase. The transporters measure 6 1/2 feet wide by 12 foot long deck with an additional 15" sticking out one end for the propane tanks and computer display screen. The transporters, whether operating singularly or in tandem, are controlled by a wireless hand held controller. These transporters are each rated at 110,000 pounds capacity. They have a deck height of 18-1/2" in the lowered position, with a total lift stroke of 6 inches. These particular transporters have two sources of power. A propane conversion gas engine drives a generator which in turn powers the wheel motors hydraulic power pack for the fluid suspension system. The alternate power source is an umbilical line to shore power as a back up and for use when entering a clean room environment. | |

|

SOLVING LIGHTER DUTY WHEELED VEHICLES |

|

|

|

|

|

Electric wheeled Solving Transporter meets the requirements of a clean

and dust free environment in the transformer industry.

|

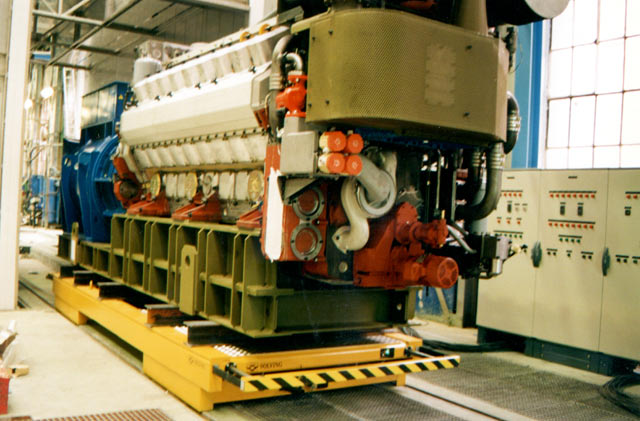

|

Heavy diesel engines are moved through assembly with a wheeled handling

system from Solving.

|

AMERICAN SOLVING INC

6519 EASTLAND PLAZA • BROOK PARK, OHIO (USA) 44142

PH. 440-234-7373 • PH. 800-822-2285 • FAX 440-234-9112

e-mail: sales@solvinginc.com